- BUSINESS

- Quality Management

- Overview

We believe differentiated total service maximizes value of clients. Non-destructive test and quality inspection service are providedthrough experienced inspectors certified by domestic and overseas institutions and latest test equipment developed by DSEC. We also provide repair service for operating LNGCs and CCS construction from procurement to installation, quality management and test.

We believe differentiated total service maximizes value of clients. Non-destructive test and quality inspection service are providedthrough experienced inspectors certified by domestic and overseas institutions and latest test equipment developed by DSEC. We also provide repair service for operating LNGCs and CCS construction from procurement to installation, quality management and test.

We believe differentiated total service maximizes value of clients. Non-destructive test and quality inspection service are providedthrough experienced inspectors certified by domestic and overseas institutions and latest test equipment developed by DSEC. We also provide repair service for operating LNGCs andCCS construction from procurement to installation, quality management and test.

Business Field

Business Field

Non-Destructive Testing

(NDT)

(NDT)

Quality Management

(QM)

(QM)

LNGC construction inspection

& Repair ship Business

& Repair ship Business

Non-Destructive Testing

(NDT)

(NDT)

Quality Management

(QM)

(QM)

LNGC construction inspection

& Repair ship Business

& Repair ship Business

Non-Destructive Testing (NDT)

Comprehensive non-destructive test service is provided from fabrication and installation to NDT map drawing, coordination, various non-destructive test, and technical consulting & superintendent for ships, onshore & offshore plants, steel frame, and bridge

| Main Tasks |

|

· Advanced PAUT & TOFD

Since the test method of TOFD was introduced at first, DSEC has developed various test methods, and our inspectors, who have international certifications(ASNT & ISO 9712) and experiences in diverse fields, have applied PAUT & TOFD as an alternative of RT the international certificate during ship & offshore projects.

- - Specialized material inspection : Stainless steel, Clad, Duplex, Inconel, A182-F22

- - Heavy-wall Inspection : Structure(over 100t) & Pipe

- - Stainless steel(with weld-crown condition, under 12t) test method(approved by Class)

- - In-service inspection : Vessel, Heat exchanger, High pressure pipe, Ball tank

- - Inspectors holding ASNT & ISO 9712, Chevron Qualification relevant with PAUT

Since the test method of TOFD was introduced at first, DSEC has developed various test methods, and our inspectors, who have international certifications(ASNT & ISO 9712) and experiences in diverse fields, have applied PAUT & TOFD as an alternative of RT the international certificate during ship & offshore projects.

- - Specialized material inspection : Stainless steel, Clad, Duplex, Inconel, A182-F22

- - Heavy-wall Inspection : Structure(over 100t) & Pipe

- - Stainless steel(with weld-crown condition, under 12t) test method(approved by Class)

- - In-service inspection : Vessel, Heat exchanger, High pressure pipe, Ball tank

- - Inspectors holding ASNT & ISO 9712, Chevron Qualification relevant with PAUT

· Rad Guard system

- - First development of Rad Guard system in Korea to set the radiation controlled area 2m away from the radioactive source (dose: 1 uSv/hr)

- - Big contribution to reduce the construction progress without evacuation and disruption to operations

- - First development of Rad Guard system in Korea to set the radiation controlled area 2m away from the radioactive source (dose: 1 uSv/hr)

- - Big contribution to reduce the construction progress without evacuation and disruption to operations

Radio Graphic Examination

Time of Flight Diffraction

Phased Array Ultrasonic Examination

Quality Management

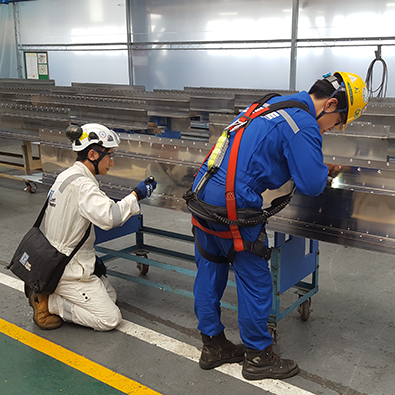

Our quality inspection services for shipbuilding and offshore projects are carried out by experienced inspectors certified by international institutions, available for every production stage from factory acceptance test to commissioning and hook up. Also we carry out In-process inspection, which shortens the inspection period and preemptively removes possible quality issues.

| Major Inspection Field |

|

Factory Acceptance

Structure

Piping

Mechanical

Electrical

Commissioning

LNGC construction inspection

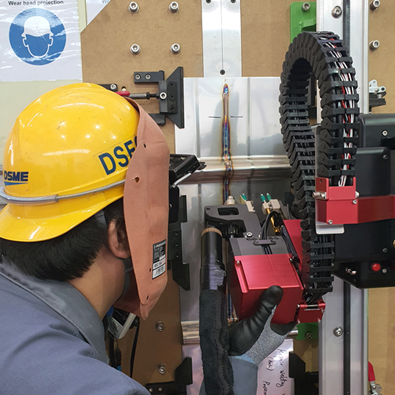

DSEC provides timely solution for quality issue and preventative action based on our track record of more than 100 LNGC construction and accumulated expertise.

| Major Inspection Field |

|

Insulation Box Fabrication inspection

Spray Nozzle Fabrication inspection

Invar Tube Fabrication inspection

Insulation Box Fit Up inspection

Membrane welding inspection

Helium Leak Test by auto carriage

CCS installation & In-service LNGC repair

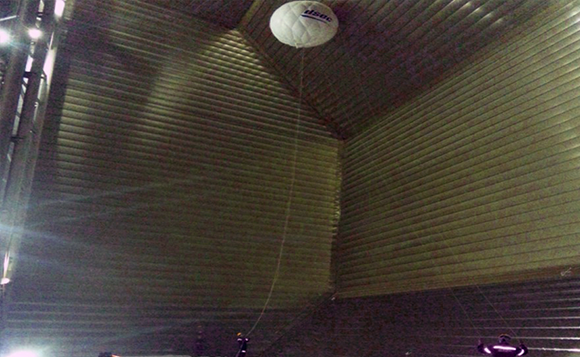

DSEC provides integrated services including material supply, installation and qualify inspection in the fields of CCS installation for new building of LNG carrier, bunkering vessel & fuel tank. Also we provide total service from pre-tests, materials supply & repair to final test for in-service LNGC(GTT NO & Mark type) with the shortest period securing high quality and safety in Singapore, Malaysia, Qatar, etc.

| Main Tasks |

· Removing and installation of the membrane & insulation panel as per GTT & Class specification (Welder, Bonder and athorized qeuipment) · Helium test(by balloon, manual & auto carriage), Secondary & Primary Barrier Global Test, Vacuum box test

|

| Clients List |

|

Membrane cutting

Triplex bonding

.png)

Membrane welding

Helium test by balloon

CCS Training Center

To provide immediate and high quality service to all over the world, DSEC operates the training center with highly skilled manpower certified by GTT & class societies, various mock-up and advanced equipment.

Procedure qualification test for Welding, Bonding & Mastic

Procedure qualification test for Welding, Bonding & Mastic

Training & qualification test for Welder, Bonder & Equipment operator

Training & qualification test for Welder, Bonder & Equipment operator

Machine performance test for Welding & Bonding

Machine performance test for Welding & Bonding Macrographic test for Welding specimen

Macrographic test for Welding specimen

Plasma auto welding

Mastic dispenser

Auto bonding

Macrographic test

Mock-up

Mock-up

View Quality Management Brochure >>

View Quality Management Brochure >>

CONTACT USKOREANSITEMAP

Head office: 67, Chungjang-daero13beon-gil, Jung-gu, Busan, Korea

COPYRIGHT DSEC ALL RIGHT RESERVED.